Going Green Makes A Good Investment

Facing a perfect storm of rising power costs, increasing demand for bandwidth and the resultant strain on existing facilities, the cable industry is looking for ways to reduce energy consumption and to increase access to alternative sources.

Specifically, according to Society of Cable Telecommunications Engineers (SCTE) statistics, in 2010, the cable industry paid some $1 billion for electricity. Should network growth be 50 percent by 2017, estimates show the power bill increasing to $2.5 billion annually. Bump growth to 100 percent, and the bill jumps to $3.5 billion.

Says Paul Shmotolokha, president and co-founder at Coppervale Enterprises, "Those who prepare their networks and optimize for efficiency will be in the best competitive position going forward. If you don’t pay attention now, when energy costs go through their next cycle, it will be a death knell if you are not ready.”

Low-Hanging Fruit

One of the simple ways operators are preparing is by profiling energy usage and performing utility audits to determine how they buy and consume power. Armed with this information, they can save between 5 percent and 10 percent by engaging in competitive bidding in a deregulated state and by negotiating with the utility in a regulated one, for example.

"Some customers are paying the high industrial rates 24 hours (a day) where, at night time, they should be paying the lowest levels," Shmotolokha adds.

Cox Enterprises, the parent company of Cox Communications, realized that by not having a centralized accounts payable, it couldn’t compare power usage across locations easily. Cox recently contracted with a company called Urjanet, which parses through utility bills and translates the information into data fields for manipulation.

"What that gives us is real-time electric information from consumption to price," notes Steven Bradley, director of engineering/Alternate Energy and Business Continuity at Cox Enterprises. “The data can be manipulated to find and fix anomalies.”

Smart Investing

Tracking power consumption is just one of the components of Cox Conserves, a program the company implemented in 2007 with the overall goal of reducing its carbon footprint 20 percent by 2017. It has included everything from encouraging behavioral changes to recycling programs to reducing fleet emissions. To date, Cox has implemented more than 120 alternative energy projects, and it’s on track despite having to "get creative" with the economic downturn, Bradley adds.

The good news is that while, in this period of recession, other investment returns have gone down, energy conservation and alternate energy investments have remained consistent. "They look a lot more attractive than other things out there in terms of what you put your capital dollars into. It is a great conservative investment and you know what the return is going to be," Bradley explains.

One of the most recent developments for Cox has been the installation of fuel cells to help power facilities in the California cities of Rancho Santa Margarita and San Diego. The state, which offers incentives for alternative energy projects, is experiencing skyrocketing energy costs due to congestion on the distribution and transmission system.

The Rancho project is an 800-kilowatt (kW) fuel cell, which produces 60 percent of the location’s power. In San Diego, one facility (an administrative office and data center) has a 400 kW fuel cell that provides 60 percent of the electricity, while a second facility (a headend) has a 400 kW fuel cell that provides 100 percent of the electricity on an annual basis.

The first two installations have administrative offices coming in during the day, so the load is not flat. "We (tried) to size for a minimum based load. We don’t want to be in a situation where we are exporting lots of power back to the utility at night," Bradley says.

Although Cox would not give specifics with regard to ROI, Bradley says the company expects to recoup costs for the fuel cells "fairly quickly."

"We run biogas in the fuel cells, which costs a premium above natural gas. But even with the expensive gas to make it a renewable green source, we are still able to produce electricity cheaper than we can buy it," he says.

While Cox’s installations were done at existing facilities, Oregon’s BendBroadband started with a clean slate when it set out to build a new network operations center. The company decided to invest an extra million dollars to make the Vault environmentally sound and expects the ROI to be approximately 10 years.

"The power data centers consume is out of proportion to the number of jobs and land they take up…The amount of power that data centers consume has been growing at a very rapid rate over the last five years. So knowing all of this, we wanted to build a data center that didn’t continue that trend," explains Leonard Weitman, vice president/Technical Operations at BendBroadband.

Powering The Vault

The Vault is used for the operator’s needs as well as to serve commercial customers. According to the carrier, the Vault is central Oregon’s only Tier III colocation data center. Here are some key points regarding the Vault’s power ops:

Solar panels fill the south side of the data center’s roof and, today, with the facility at 25-percent capacity, solar energy meets almost all of the data center’s powering needs. Once the building is fully occupied, solar will account for one-sixth of the total power consumed.

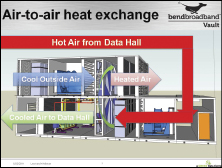

Taking advantage of Oregon’s climate, the cooling system draws outside air into a heat exchange wheel. The hot air from the data center is cooled and rotated back inside.

Enterprise customers require a mission-critical facility that guarantees business continuity. Uninterruptible power supplies bridge the gap between when the utility power goes out and the emergency generators kick in.

While a traditional data center uses a large string of batteries, BendBroadband chose a system that utilizes heavy, spinning flywheels. If the power goes out, stored energy keeps them spinning so that each can generate electricity for 25 seconds. "We avoided the environmental mess of the lead and acid of batteries," Weitman says, noting that the company has also avoided the cost of replacing and disposing these batteries, which have a limited shelf life.

SCTE’s Success Story

In the meantime, SCTE’s Smart Energy Management Initiative (SEMI) also have recognized the powering challenges the cable industry faces as it seeks to propel itself deeper into business services. The Sustainability Management Subcommittee has been working on recommended environmental practices for the buildings and equipment related to critical facilities.

The hope is that SMS 001, "Recommended Energy Conservation, Sustainability and Efficiency Practices for Critical Systems," will be published in time for Cable-Tec Expo this month in Atlanta and that SMS 002, "Product Environmental Requirements for Cable Telecommunications Facilities," will follow in 2012. In regards to SMS 003, an adaptive power systems interface standard that deals with transactional energy consumption, SCTE President Mark Dzuban says it is possible the industry will see hardware by 2014.

In addition, the SCTE continues to put its money where its mouth is. While SEMI has been making recommendations for the cable industry, the SCTE has been working to put them into practice at its Exton, Pa., headquarters. Last spring, the organization announced that by doing things like replacing high-wattage lighting with LED and the installation of a solar system it has achieved 46-percent cost reduction in electricity from the grid.

Most recently, the SCTE, in partnership with Alpha Technologies and Comm-Scope, put together a 19.7 kW hybrid back-up power system that combines a 8 kW hydrogen fuel-cell solution, with a 2.8 kW grid interactive solar array and 20-hour-runtime storage batteries. The installation was tested when Hurricane Irene struck the East Coast earlier this year.

"Irene was trial by wind and rain. It proved that this system does work. When I walked into the building to check on the physical conditions, I opened the server room door. All systems were on and operational," says Derek DiGiacomo, SCTE’s director of information systems and head of SEMI.

The various components of the system are designed to work together to provide maximum run time. Without a solar assist, it could provide four days of back-up power. With the sun in the summer, there could be an additional 19.8 hours while, in the winter months, this extra time would amount to about 8.34 hours, based on the SCTE load of 1.5 kW.

"During Irene, we didn’t see sunlight substantial enough until the third day. The three lines of defense marry and really work well," DiGiacomo says.

|

| FIGURE 1: Taking advantage of Oregon’s climate, the cooling system draws outside air into a heat exchange wheel. The hot air from the data center is cooled and rotated back inside. |

The hybrid system, with a 3.6-kW inverter, could handle twice the load required by SCTE, but the run times would be cut in half. "The inverter could be replaced with 6 kW, and then it would be able to take on a load four times the size of SCTE," comments Jim Heidenreich, vice president/Product Management and Customer Fulfillment at Alpha. In other words, the system could be scaled an replicated for additional installations.

As for ROI, the total cost of ownership must be taken into account. For example, Mark Alrutz, director/Worldwide Technical Sales and Service at CommScope, says, "Size for size a diesel generator will be less expensive right out of the gate. But it requires significant maintenance and upkeep, whereas the hydrogen fuel cell has very few moving parts. The only maintenance is the change out of a $25 filter."

The Green Pavilion

In addition to being SEMI program sponsors, Alpha and CommScope will be part of the expanded Green Pavilion at Cable-Tec Expo this year. One thing that excites CommScope is its fan-based shelter cooling system. In the event of a grid failure, powering the air-conditioning system places a lot of load on the back-up system.

"If you can utilize outside air and pull it through the site to keep temperatures down, you can extend time that backup systems can work," Alrutz says.

In Atlanta, Alpha will launch a line of next-generation outdoor power supplies. Although the company was mum on specifics, Heidenreich did mention the company expects these new products to improve operating expenses by 3 percent or 4 percent compared to their previous iterations.

Monta Monaco Hernon is a frequent contributor to Communications Technology. Contact her at mcmhern@yahoo.com.