Energy Matters

By Chris Bastian

Senior Vice President/CTO; SCTE/ISBE

The cable industry has focused its sights on energy management. Energy management assesses what the minimum amount of energy is to achieve an organization’s or, at a more micro-level, a region’s or facility’s needs, and plots what is necessary to meet those energy goals. It includes the study of:

- Alternative energy sources

- Facility climate technologies

- Energy efficiency of network equipment, whether in the access network, outside plant, hub site or data center

- Fleet optimizations

Not only is energy management the right thing to do as good corporate stewards of the environment, but through wise energy management, cable operators can save billions of dollars in deferred energy costs.

SCTE/ISBE founded the Energy 2020 program in 2014. The Energy 2020 program goals are:

- Improve Energy Consumption by 20% on a unit basis

- Improve Energy Cost by 25% on a unit basis

- Optimize Critical Facilities and Data Centers by 20%

- Provide 10% of total energy from off-grid sources

The program currently encompasses many cable operators around the globe. All SCTE/ISBE member companies are encouraged to participate. Each operator maintains its own priorities and areas where it focuses its energy management efforts.

Per ISO 50001, the energy management process is:

- Develop a policy for more efficient energy use

- Set energy objectives in line with the policy

- Use data to make informed energy decisions

- Measure the results

- Review the policy’s effectiveness

- Continually improve energy management practices

In accordance with this process, last year the Energy 2020 program focused on baselining 2014 metrics data and generated 15 energy-related standards and operational practices:

- SCTE 184 2015: SCTE Energy Management Operational Practices for Cable Facilities

- ANSI/SCTE 186 2012: Product Environmental Requirements for Cable Telecommunications Facilities

- ANSI/SCTE 203 2014: Product Environmental Requirements for Cable Telecommunications Facilities—Test Methods

- SCTE 208 2014: Cable Operator Carbon Data Collection Recommended Practices

- ANSI/SCTE 210 2015: Performance Metrics for Energy Efficiency & Functional Density of Cable Data Generation, Storage, Routing, and Transport Equipment

- ANSI/SCTE 211 2015: Energy Metrics for Cable Operator Access Networks

- SCTE 212 2015: Cable Operator Energy Audit Framework and Establishment of Energy Baseline

- SCTE 213 2015: Edge and Core Facilities Energy Metrics

- SCTE 216 2015: Adaptive Power Systems Interface Specification (APSIS™)

- SCTE 218 2015: Alternative Energy, Taxes, Incentives, and Policy Reference Document

- SCTE 219 2015: Technical Facility Climate Optimization Methodology

- SCTE 225 2015: Cable Operator Fleet Maintenance and Vehicle Selection Operational Practice

- SCTE 226 2015: Cable Facility Classification Definitions and Requirements

- SCTE 228 2016: Inventory of Energy Efficiency Practices for Broadband Provider Facilities

- SCTE 229 2016: Operational Practice for Cable Facility Design Process

This year, the program is collecting the same energy metrics from 2015 to compare against the 2014 baseline.

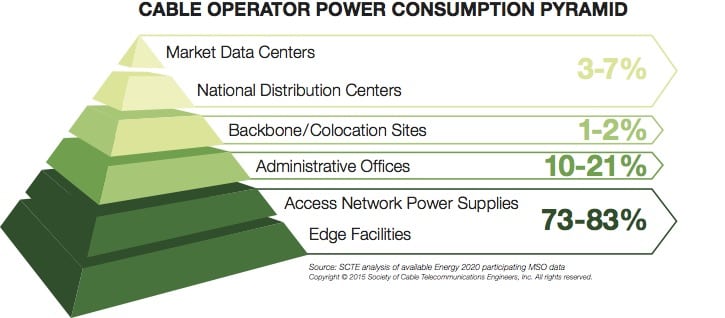

Through studying cable operator energy consumption data, the program has established the “Energy Pyramid,” shown below, which illustrates that edge facilities and access network power supplies account for between 73% and 83% of a cable operator’s power consumption. Therefore, even small improvements in this section of the network can yield dramatic energy savings.

We are reaching out to both the operator and vendor communities to increase participation and to announce our progress. We have tremendous program buy-in from many executives across the cable industry. We ask that more companies join us as we focus on conserving energy and, as a result, save significant operational dollars.